Short-Term Energy Storage in a Net-Zero Future

In this post from NET-ZERO:

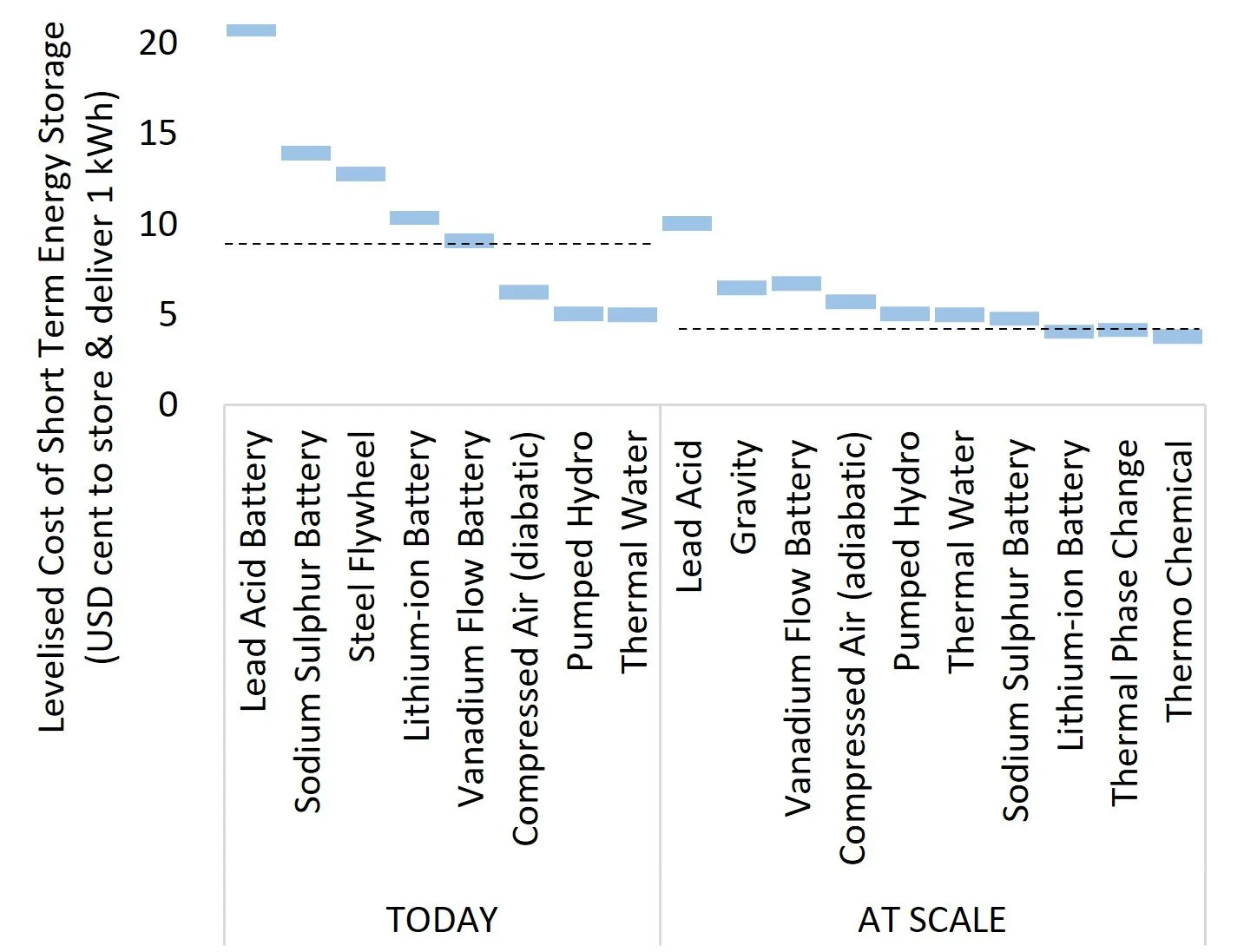

Which energy storage technologies are most promising for short-term energy storage? The physical and cost attributes of Lithium-ion batteries and pumped hydro make them the leading candidates for short duration grid storage.

Which other technologies might help with short-term grid electricity storage? Vanadium flow batteries, sodium sulphur batteries, gravity storage, thermal, and compressed air - the pros and cons.

Is there enough lithium in the world to produce enough batteries for grid storage and electric cars? Why less than 1/3 of known lithium resources can create enough battery storage for the grid and cars.

Short Term Energy Storage: Physical Properties and Economic Costs

Short term energy storage will be used to store wind and solar electricity generation in a Net-Zero future - helping to smooth the variability of wind and solar electricity generation and ensure the provision of a stable and reliable energy supply over minutes, hours, and days. (for information on Long-Term energy storage click here).

Short term energy storage requires technologies suited to a daily charge and discharge cycle with low energy leakage, reasonably high roundtrip efficiency, durability, sufficient resources, low carbon credentials, and low cost per kWh storage capacity. (for a description of storage technologies click here)

Based on the above selection criteria we can rule out several technologies straight away:

Flywheels leak 15% of energy every hour so are not suitable for use over hours or days.

Electricity-to-hydrogen-to-electricity has low roundtrip efficiency, so you only get back 25% of what you put in, which makes a poor candidate for daily storage.

Lead acid batteries have low durability and can only survive 1,000 charge and discharge cycles and will not last long enough.

That leaves us with pumped hydro, lithium-ion, sodium sulphur, vanadium flow, and gravity. Let’s compare the economics. For comparison we will assume each of our storage options is charged up with cheap (fully scaled) solar electricity at $2c per kWh and then cycle the system once per day.

Pumped Hydro Energy Storage

Pumped hydro is the mainstay of electrical storage technology today and with a levelised cost of around $5c per kWh (including cheap solar charging) is still the cheapest way to time shift power. Current global capacity of pumped hydro is around 9 billion kWh but a recent report, by Andrew Blakers from the Australian National University’s R100 group, estimates there are another half a million sites globally which could store an estimated 22,000 billion kWh. That’s 150 times our required future short term storage. Pumped hydro is a good bet.

Lithium-Ion Energy Storage

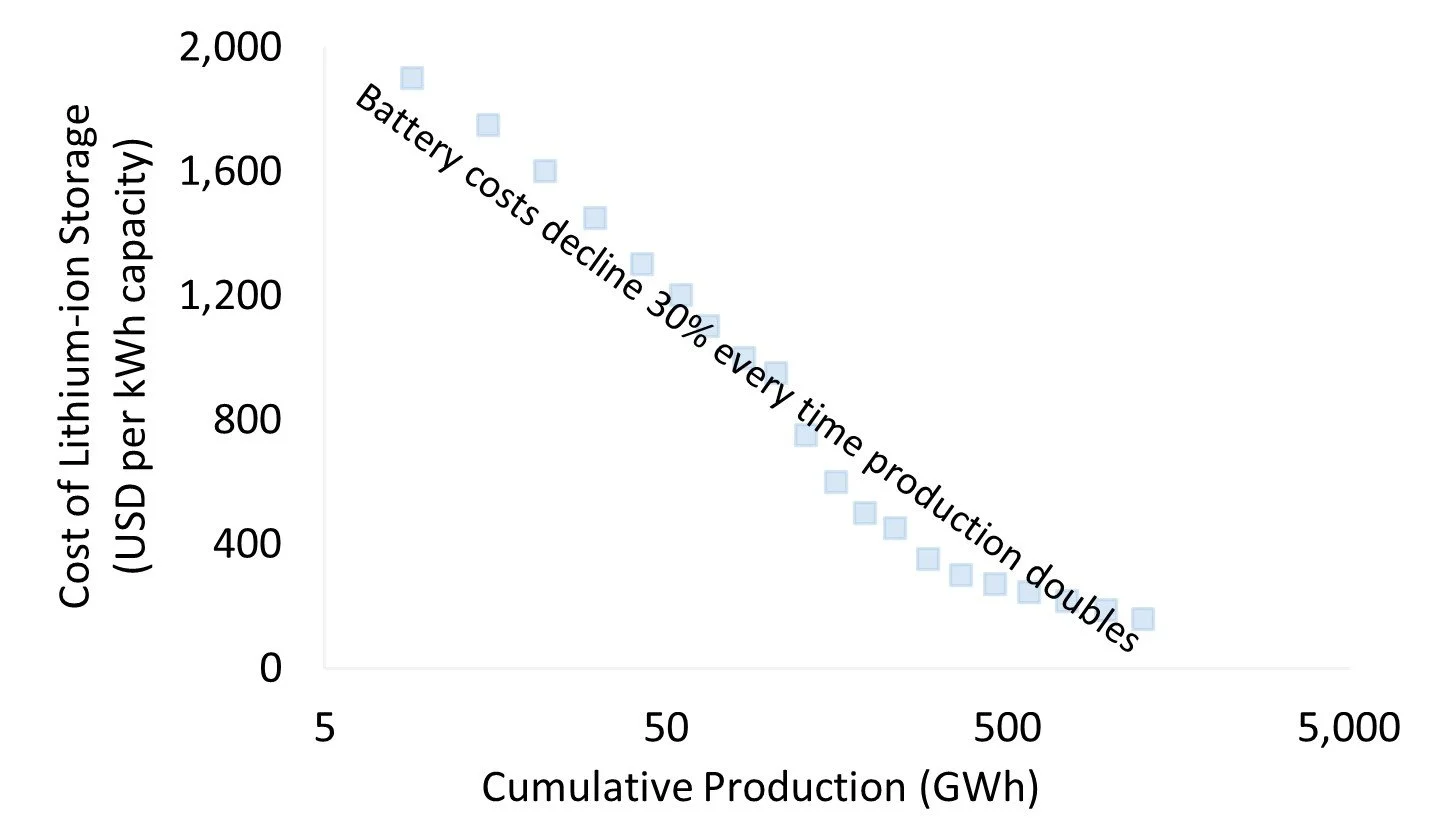

Lithium-ion batteries are becoming one of the most promising technologies for short term energy storage. The onset of electric vehicles has driven down the cost of lithium-ion by over 90% in the last 20 years. The experience curve is running even faster than solar with a 35% cost reduction every time installed capacity doubles. Lithium-ion technology has high efficiency, a robust life expectancy, plentiful supply and competitive costs. If we assume lithium-ion batteries serve one third of our short-term storage on the grid and the majority of passenger car needs, then the produced capacity needs to double another 6-7 times over and the experience curve predicts costs reaching below $50 per kWh without violating the floor price. Costs of cheap solar generation plus lithium-ion battery storage could fall from $10c per kWh today to below $4c per kWh at scale – cheaper than gas or coal electricity.

Is there enough Lithium? There are an estimated 17 million tonnes of quantified lithium reserves on Earth and another 63 million tonnes of resources yet assessed for cost of extraction. Lithium-ion batteries consume 100 g of lithium per kWh. So, building out 140 TWh of short term storage (enough to stabilise the future electricity grid) requires a total 14 million tonnes of lithium. If all 1 billion cars on Earth were swapped for long range electric vehicles this would consume another 10 million tonnes (1 billion x 100 kWh x 100g lithium per kWh). So roughly one third of known resources provide enough lithium for both short term grid storage and electric cars.

One of the largest lithium-ion storage installations completed to date is South Australia’s $60 million facility supplied by Elon Musk’s Tesla in 2018. The installation started off as a Twitter bet after the Australian Prime Minister Malcolm Turnbull blamed storm related power outages on renewable energy intermittency.

The head of Tesla’s battery division Lyndon Rive, got wind of his complaints, and claimed Tesla could build 100-300 MW of battery storage in 100 days and solve the power grid problems. Elon Musk raised the stakes over Twitter by promising to finish it in less than 100 days or Australia could have it for free.

All parties agreed and Tesla delivered the installation with 40 days to spare.

This installation has proved very profitable and has triggered a wave of large-scale lithium-ion battery installations across the world. A trend likely to continue.

Compressed Air Energy Storage

Where lithium-ion is very flexible in size, compressed air is an interesting technology option for larger storage projects. There are only a handful of facilities in the world today and the technology is still being developed. Storage costs are cheap but due to technical challenges which require the use of natural gas to re-heat the cold expanding air, the roundtrip efficiency is low. Next generation designs should eliminate the need for natural gas heating and improve the overall efficiency.

If the capital costs can be kept down then compressed air storage could prove an interesting option for larger scale, shorter term, energy storage facilities.

Vanadium Flow Energy Storage

Vanadium flow batteries have a similar cost profile to lithium-ion today, are durable and highly scalable. However, potential cost reductions are limited by the price of vanadium and global resources limit the number of batteries which could be made. Vanadium flow will probably play a more minor role in grid storage.

To produce Vanadium flow batteries, every kWh of storage capacity requires more than 3.5 kg of vanadium. The remaining 63 million tonnes of vanadium left on the planet will only support 10% of the 140 TWh of short-term storage we might need.

Gravity Energy Storage

Gravity batteries are still in the design phase but have the potential to provide an alternative to pumped hydro where the local geography cannot accommodate a reservoir. If initial cost estimates prove correct the technology can provide comparable economics but caution must be used surrounding the CO2 emissions from large scale use of concrete.

Sodium Sulphur Battery Energy Storage

Sodium sulphur is relatively expensive today, but given the cheap materials used for manufacture, there is no reason it cannot be competitive once scaled up. The technology roadmap is not as clear as lithium-ion but if properly developed sodium sulphur could provide an interesting technology route especially for warmer locations.

Demand Side Response

Demand side response is our final option. Around 30% of total energy demand could be eligible for remotely turning on and off and let’s assume 50% of this energy use is accessible for 1 hour per day. That adds up to 0.6% of daily energy use or the equivalent of two billion kWh per day. A long way from the 140 billion kWh of short-term storage capacity we are looking for in a Net-Zero future, but a very helpful resource to call upon in times of exceptionally high demand or low supply.

If we add up the areas of energy use which could be temporarily shut down for demand response it would include the metals, chemicals, and paper industry, alongside heating and cooling applications both commercial and residential. This adds up to 30% of total energy demand.

Electric vehicle batteries are another storage facility we could tap. Assuming there are 1 billion cars globally, each with a 100-kWh battery and their owners allow 15% cycling per day, this could provide another 15 billion kWh of energy storage, more than 10% of our required total and especially useful in countries with high car penetration. Variable electricity tariffs are another form of demand response which can be used to encourage, for example, overnight electric car charging to help balance demand to best suit the grid

Summary

Overall, pumped hydro and lithium-ion battery technologies should be able to provide much of the short-term electrical storage solution. Thermal storage solutions can be used for low grade heat applications and compressed air, vanadium, sodium sulphur, gravity batteries, and demand side response can play a supporting role.

This blend of technology brings the average levelised capital cost of short term storage today to $4-5c per kWh with a 75% roundtrip efficiency and total cost including charging with cheap solar at just under $10c per kWh.

Once the technology is scaled, costs will halve and efficiencies will improve by 5-10%, bringing the total cost to generate and store renewable electricity to less than $5c per kWh – cheaper than fossil fuels ($5c per kWh) and remember less than half of renewable electricity generation will require storage.

Click to find out more about the Lifecycle Emissions of Different Energy Supply Options & How Much Land is Used by Renewables and Other Energy Sources

Want to take action and help fight climate change - find more resources in Climate Action